Page 45 - Catalog 15

P. 45

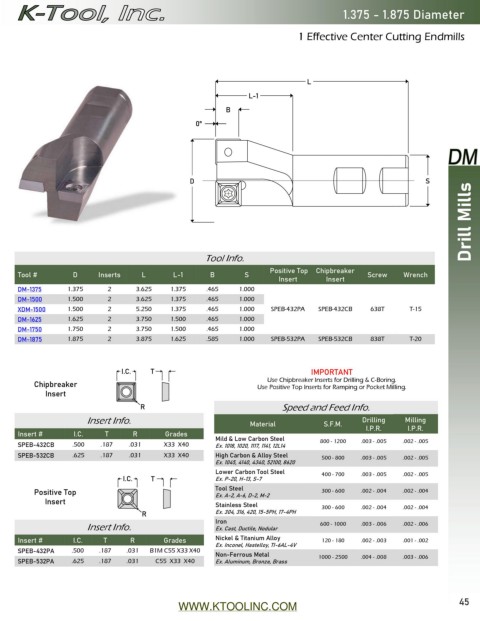

1.375 - 1.875 Diameter

1 Effective Center Cutting Endmills

L

L-1

B

0°

D S

Drill Mills

Tool Info.

Positive Top Chipbreaker

Tool # D Inserts L L-1 B S Screw Wrench

Insert Insert

DM-1375 1.375 2 3.625 1.375 .465 1.000

DM-1500 1.500 2 3.625 1.375 .465 1.000

XDM-1500 1.500 2 5.250 1.375 .465 1.000 SPEB-432PA SPEB-432CB 638T T-15

DM-1625 1.625 2 3.750 1.500 .465 1.000

DM-1750 1.750 2 3.750 1.500 .465 1.000

DM-1875 1.875 2 3.875 1.625 .585 1.000 SPEB-532PA SPEB-532CB 838T T-20

I.C. T IMPORTANT

Use Chipbreaker Inserts for Drilling & C-Boring.

Chipbreaker Use Positive Top Inserts for Ramping or Pocket Milling.

Insert

R Speed and Feed Info.

Insert Info. Material S.F.M. Drilling Milling

Insert # I.C. T R Grades Mild & Low Carbon Steel I.P.R. I.P.R.

SPEB-432CB .500 .187 .031 X33 X40 Ex. 1018, 1020, 1117, 1141, 12L14 800 - 1200 .003 - .005 .002 - .005

SPEB-532CB .625 .187 .031 X33 X40 High Carbon & Alloy Steel 500 - 800 .003 - .005 .002 - .005

Ex. 1045, 4140, 4340, 52100, 8620

Lower Carbon Tool Steel 400 - 700 .003 - .005 .002 - .005

I.C. T Ex. P-20, H-13, S-7

Positive Top Tool Steel 300 - 600 .002 - .004 .002 - .004

Ex. A-2, A-6, D-2, M-2

Insert Stainless Steel

R Ex. 304, 316, 420, 15-5PH, 17-4PH 300 - 600 .002 - .004 .002 - .004

Iron

Insert Info. Ex. Cast, Ductile, Nodular 600 - 1000 .003 - .006 .002 - .006

Insert # I.C. T R Grades Nickel & Titanium Alloy 120 - 180 .002 - .003 .001 - .002

Ex. Inconel, Hastelloy, TI-6AL-4V

SPEB-432PA .500 .187 .031 B1M C55 X33 X40 Non-Ferrous Metal

SPEB-532PA .625 .187 .031 C55 X33 X40 Ex. Aluminum, Bronze, Brass 1000 - 2500 .004 - .008 .003 - .006

45

WWW.KTOOLINC.COM